The Future of Cross Laminated Timber in Education Construction

Author

Carol Heneghan

Senior Framework Manager

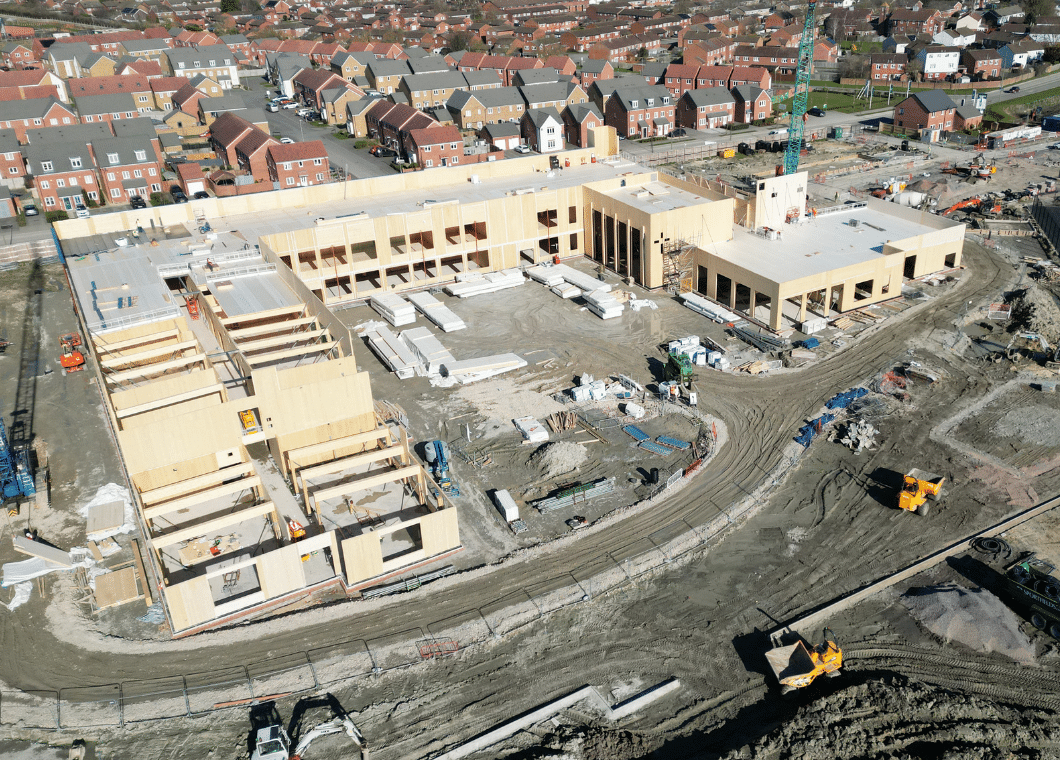

As the construction industry continues its drive toward sustainability and net-zero targets, Cross Laminated Timber (CLT) is increasingly being viewed as a preferred solution with the education sector presenting as a key opportunity to use timber construction methods. At Bouygues UK, our work on St John’s CE Academy in Wantage, where we are delivering one of the largest CLT frames for the Department for Education (DfE), has provided us with valuable insights into both the opportunities and challenges of this low-carbon material.

CLT is not new, but it is only recently gaining momentum in UK education construction. It offers significant advantages: lower embodied carbon, faster build times, and a better internal environment for pupils and staff. At St John’s, we’ve seen a reduction in embodied carbon of up to 40%, a 25-40% cut in programme duration, and clear benefits in terms of thermal and acoustic performance.

Yet, as an industry, we must ask: are we setting too many parameters that limit CLT’s potential? And are we sharing knowledge effectively enough to ensure it becomes a viable and scalable solution for future education projects?

CLT: The Sustainable Ideal

There is no doubt that CLT aligns perfectly with sustainability ambitions. It is a renewable material, it acts as a carbon sink, and it supports modern methods of construction through off-site manufacturing. The biophilic appeal of exposed timber in schools also brings softer, human-centred benefits like improved cognitive function, reduced stress, and a generally more nurturing learning environment.

In this respect, CLT is not just a technical material choice; it’s a design philosophy. The question is not whether CLT should have a place in the future of education construction — it absolutely should. The real question is: how do we make that happen?

Learning from St John’s CE Academy

Our experience at St John’s CE Academy demonstrates that CLT is feasible — even for large-scale DfE projects — when there is a clear sustainability driver and early-stage buy-in. Partnering with specialist supplier Eurban, we delivered a CLT frame that met DfE OS21 standards, was installed over just 18 weeks, and helped meet airtightness and energy efficiency goals.

But the project also highlighted the systemic challenges CLT still faces:

- Limited UK expertise, both in the supply chain and on site.

- Higher upfront costs that don’t always align with GIFA benchmarks.

- Over-engineering for fire and acoustic performance, due to a lack of UK-specific data.

- Moisture sensitivity, requiring strict site management.

These challenges are not insurmountable, but they are symptomatic of an industry still catching up with the material’s potential.

Breaking Down the Barriers

For CLT to thrive in future education construction, a coordinated effort is needed. This means:

- Investing in testing and standards to provide greater clarity around fire performance, acoustics, and long-term durability.

- Strengthening UK supply chains to reduce reliance on European imports and build local expertise.

- Embracing MMC early in project design to ensure CLT is considered from the outset — not retrofitted into traditional procurement frameworks.

- Sharing best practices across the sector, including open access to lessons learned from real-world projects like St John’s.

At Bouygues UK, we also see an opportunity to draw more heavily on the in-house expertise of the wider Bouygues Group and their WeWood team, who bring deep knowledge of engineered timber systems from across the group.

There is a risk that, in our pursuit of standardisation and safety, we overcomplicate the use of CLT. While robust regulation is essential — particularly post-Grenfell — we must avoid creating a landscape where innovation becomes prohibitively complex or costly.

Instead, we need a collaborative approach that encourages experimentation within safe boundaries, that rewards sustainability in procurement, and brings together clients, contractors, and specialists to develop tried-and-tested solutions.

Looking Ahead

CLT can play a defining role in shaping the next generation of schools that are less carbon intensive, built faster, and designed with wellbeing in mind. But it requires long-term vision and a willingness to evolve how we design, procure, and build.

As we look to the future, we must ensure CLT does not become side-lined by complexity. As an industry, we must make it easier to choose CLT by learning from our successes, refining our processes, and championing innovation. If we do, the potential for a more sustainable, smarter education estate is well within our grasp.