The construction industry has a substantial environmental footprint, influencing everything from resource extraction to waste generation.

Globally, our industry accounts for around 40% of all solid waste, highlighting the urgent need for more efficient material use and waste reduction strategies. In the UK alone, the construction sector generates over 100 million tonnes of waste annually, with approximately 40% of this ending up in landfill. Traditional practices often prioritise cost and convenience over sustainability, leading to extensive energy consumption, habitat destruction, air and water pollution, and greenhouse gas emissions. The inefficiency in material use further compounds the issue, with estimates suggesting that 10%–15% of building materials become waste during construction. Given the pressing need to combat climate change, companies within the construction sector are increasingly implementing actions to mitigate these impacts.

At Bouygues UK, we strongly believe that adopting sustainable sourcing practices for materials is critical. This involves sourcing materials locally to reduce transportation emissions, prioritising reclaimed, recycled, and renewable materials, and ensuring that our suppliers and subcontractors adhere to responsible environmental standards. Our Sustainable Procurement Policy, which emphasises sustainability criteria, ensures that our materials are sourced from reputable sources and that 100% of our timber is harvested in a manner that is credible, conflict-free, and prevents deforestation.

Moreover, embracing the concept of circularity is essential for the industry. By integrating circular economy principles into construction practices, we can minimise resource extraction and waste generation. Designing buildings for disassembly and promoting the use of recycled and reclaimed materials fosters a more sustainable construction approach. This not only reduces the need for new material extraction but also helps in reducing waste generation.

One of the most pressing challenges our industry faces is waste generation, with construction and demolition waste comprising a significant portion of global landfill volumes.

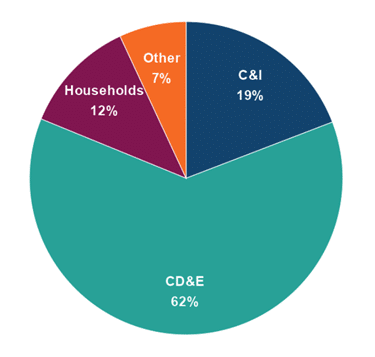

Waste generation split by source, DEFRA statistics. Construction, demolition, and excavation (CD&E) account for 62%, around three fifths of total UK waste, compared to Commercial and Industrial (C&I) – 19%, ‘Households’ – 12% and ‘Other’ activities – 7%.

It is vital for our business to implement strategies to minimise waste generation. By prioritising both the procurement of materials and the strategic design of our buildings, we can effectively reduce waste and significantly mitigate our environmental impact.

To this end, we have implemented a comprehensive framework that encourages minimal waste generation. As a testament to our commitment, we have established ambitious goals and targets to reduce the production of non-hazardous construction waste and divert it from landfill. We also prioritise sustainable material sourcing and embrace circularity, thereby ensuring a more environmentally responsible approach to construction.

Circular Economy

Construction is a resource-intensive industry, consuming large amounts of materials, energy, and water. Circular economy aims to minimise environmental impacts such as resource extraction and waste generation by promoting the reuse, recycling, and repurposing of materials.

At Bouygues UK, our aim is to develop a circular economy statement and implementation strategy for each and every one of our new projects during their early design stages. In order to meet this target, our focus is on implementing the principles of circular economy at key project phases to ensure these are embedded in the processes of designing and constructing each project.

To achieve this, we:

- Engage with our supply chain partners to foster new, innovative materials and solutions aligned with the circular economy principles.

- Ensure that the targets set out in the circular economy statement of each project are an integral part of the projects’ sustainability strategy and followed up at each RIBA stage.

- Carry out circular economy workshops at each RIBA stage to ensure that monitoring and reporting processes are in place for all projects.

- Deliver circular economy training sessions to key project team members.

Materials

Using sustainably certified products helps reduce environmental impacts, such as deforestation, while also protecting biodiversity and reducing our overall carbon footprint. Sustainably sourced materials support social responsibility and ensure legal compliance with national and global regulations. We assess responsible sourcing of materials on our non-domestic projects in line with the BREEAM certification process. We recognise that responsible sourcing must be monitored and reported for all projects, including residential developments or projects that are not assessed under BREEAM.

Our target is to ensure that 100% of timber is sustainably sourced and certified through FSC/PEFC. By 2030, we are aiming for 90% of our main construction materials* to be sustainably certified for all new projects. Additionally, we will prioritise the procurement of materials** with high recycled content across all new projects. In order to meet our target, we have committed to:

- Develop and digitalise our internal processes to ensure that appropriate data is collected and reported.

- Develop and deliver training to our site managers and procurement teams to ensure that responsible sourcing and recycling content requirements are captured.

- Engage with our designers and include responsible sourcing and recycling content requirements in the specifications on all projects at an early stage.

- Set up a monitoring and reporting processes on sustainable products at design stage, and check compliance during construction through site inspections.

- Develop and deliver training to site teams to ensure that certificates are collected and reported.

* main superstructure, substructure, internal finishes and core building services elements (BREEAM Manual)

** timber or timber-based products, concrete, metal, stone or aggregates, clay-based, gypsum, plastic, polymer, resin, paint, chemicals and bituminous, other.

Waste

One of the most significant environmental challenges faced by the construction industry is the generation of waste. With the construction industry generating 62% of the UK’s waste and 32% of all waste sent to landfill¹, reducing the waste generated by our construction activities and ensuring it is correctly managed is an essential step towards building a more sustainable future.

Monitoring and reducing the waste produced on our sites is at the forefront of our project planning and operations, with a focus on smart design, material selection, delivery, and handling of our materials.

¹Qflow Annual Waste Report 2023

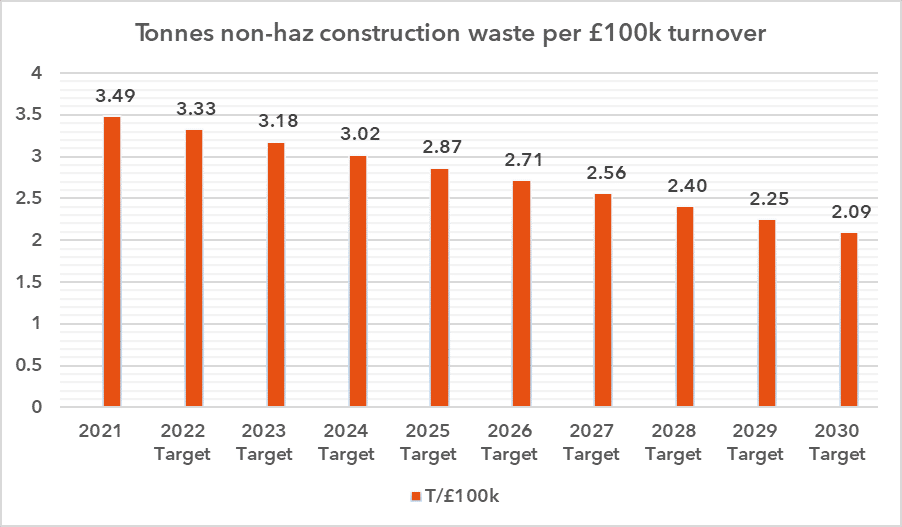

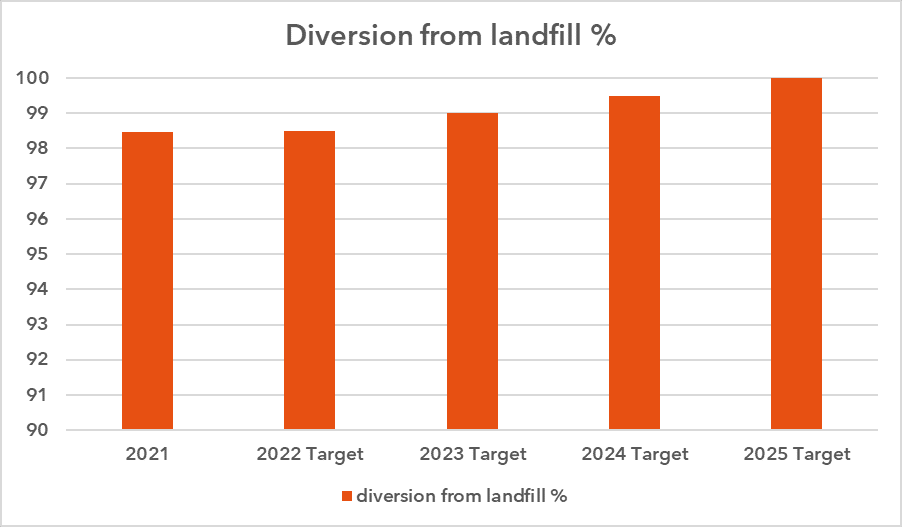

Bouygues UK has targeted a 40% reduction in non-hazardous waste production compared to 2021 figures by 2030. We are also aiming for 100% of all non-hazardous waste produced to be diverted from landfill by 2025.

Our Baseline:

In 2021, we produced 3.49 tonnes of non-hazardous waste per 100K turnover, of which 98.4% was diverted from landfill.

In order to meet our targets, we have committed to:

- Deliver ‘designing out waste’ workshops that are carried out from RIBA 2 onwards on all projects.

- Partner further with suppliers to develop and deploy take back schemes for key products.

- Engage with subcontractors ensuring that they work in line with and support the enhancement of our existing site waste management plans.

- Maximise opportunities for controlled manufacturing process for offsite construction.

- Reinforce our position on refurbishment and retrofit projects.

- Continue to work with our selected supply chain to encourage best practice, automate and streamline our data collection.

- Utilise technology i.e. Qflow to monitor live data from our sites to gain awareness, identify deviation, and develop corrective measures.

- Embrace innovative thinking to identify routes to encourage circular economy, revaluing waste as material.