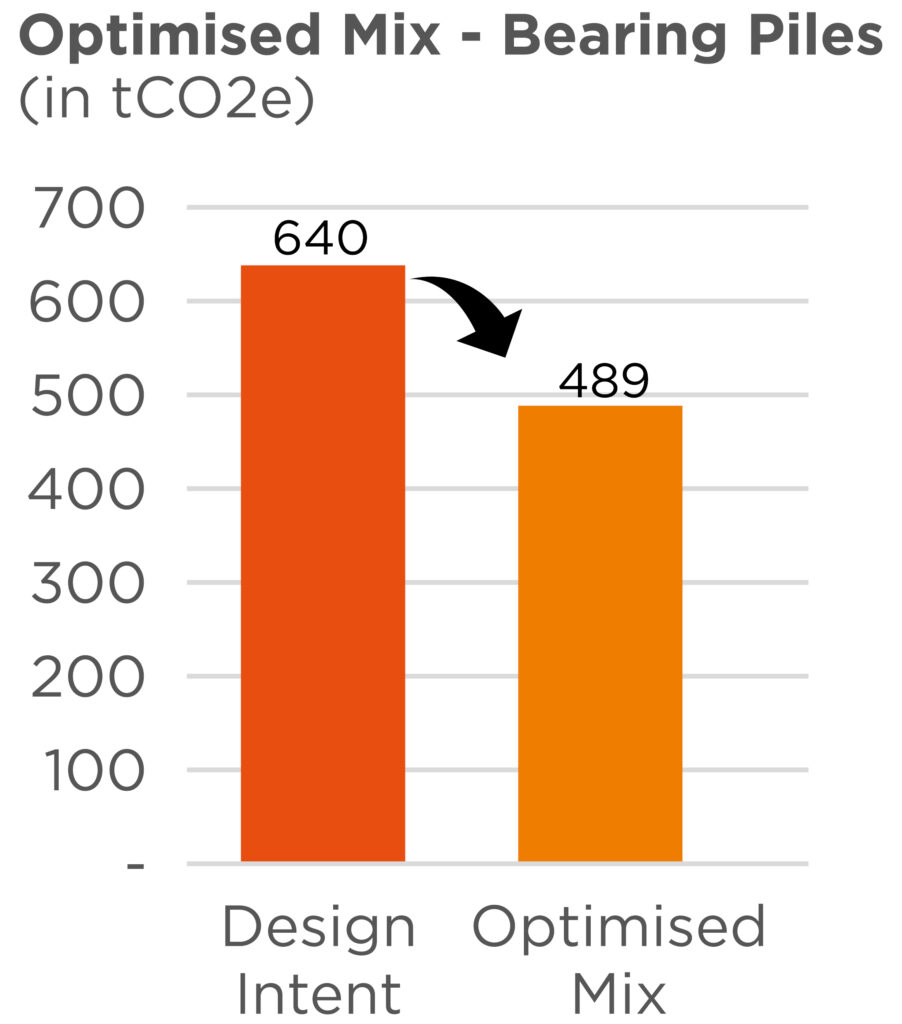

Combining a high percentage of cement replacement associated with a 56-day approach to concrete strength led to an almost 25% carbon reduction on bearing piles.

Ebury Bridge Estate is a pioneering project located in the heart of London, marking the biggest delivery of new affordable homes in South Westminster in over 50 years.

Bouygues UK is delivering the first phase of the development for Westminster City Council which comprises the first two residential blocks of 16 and 17 storeys, with a total of 226 units, and the concierge for the entire scheme.

It is well known that concrete as a material is our top carbon contributor and the team at our Ebury Bridge Estate project was determined to find a better solution with a lower carbon footprint when it came to piling on their site.

In order to reduce the embodied carbon caused as a result of piling, the site team used concrete mixes with higher percentages of GGBS (Ground Granulated Blast-furnace Slag). As GGBS is a by-product, in other words a waste product from the steel industry, its embodied carbon is much less than the production and use of regular cement (CEMI).

The team was able to incorporate this change by identifying that the bearing piles did not directly impact the critical path of the programme, allowing a high replacement rate associated with a longer curing time for the mix. The assessment for the mixes used for the piles determined that the team had reduced the embodied carbon by almost 25%.